If you are considering recessed downlights in a room with beams you must have a void between the ceiling and the floor above. This can be achieved either with a false ceiling in which the ceiling has been lowered below the height of the beams and covered with plasterboard OR having infills. This is where the spaces between each beam are battened and plasterboarded leaving the bottom of the beams exposed, thus creating the necessary void for downlights.

Downlights must be installed correctly as even a low voltage or low wattage lamps get very hot in a short period of time. When switched on a large amount of heat expels upwards and in a lot of cases can heat up the supply cable very quickly. I have been to a few calls where the light has stopped working and found the transformer [12v] scorched and supply cables burnt. The most common cause of this is due to insulation. Where a downlight is fitted, it is recommended that a diameter of 500mm above the light is not insulated . This will allow the heat to disperse safely. Supply cables should be sheathed with a heat resistant sleeve.

Next time you change a faulty lamp, make sure the light switch is off and check to see if the insulation is pushed away from the fitting above. Not only will your lamps last a lot longer, but you will avoid overheating or a fire hazard.

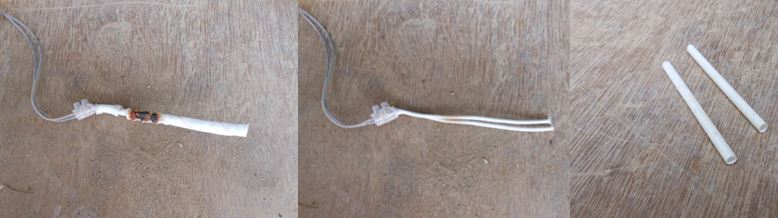

The pictures below show cable that had been scorched. Fortunately the cable was sheathed in a heat resistant cover, protecting the cable from serious damage.

RSS Feed

RSS Feed